- Home

- News

- How HVLS Fans Improve Heat Efficiency During Winter

How HVLS Fans Improve Heat Efficiency During Winter

How HVLS Fans Improve Heating Efficiency and Lower Energy Bills During Winter

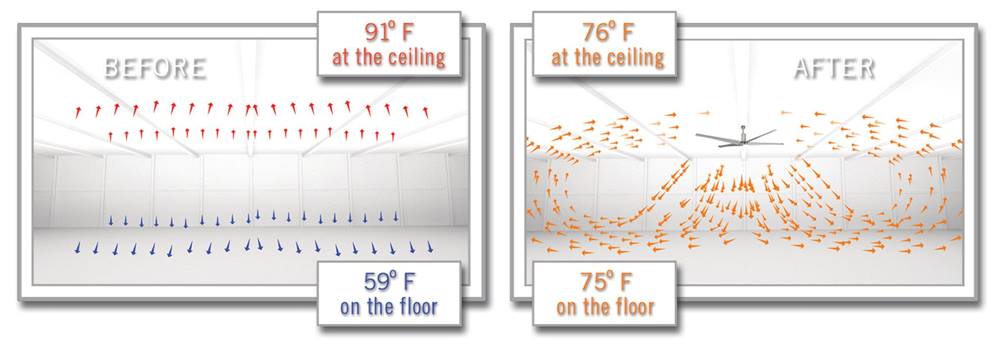

Air stratification is when warmer air rises in an enclosed space, creating layers of different temperatures from floor to ceiling. This can lead to a temperature difference of up to 30 degrees from floor to ceiling. Without proper air circulation in a high-ceiling warehouse or industrial facility setting, your company’s heating system will have to run harder, creating unnecessarily high energy bills.

Installing high-volume, low speed (HVLS) fans, however, will allow you to improve your heating efficiency and lower your energy bills during the winter months through destratification . This destratification process pushes warm air down and cycles it through the room so the temperature can remain constant at every level.

Top 5 Reasons to use HVLS Fans for Heat Efficiency

1. Provides better temperature distribution

HVLS fans are beneficial to industrial and commercial facilities in the winter because of the destratification process. When the air moves in a conical shape, heat not only gets forced back down to where employees and products are, but it also keeps air flow steady throughout the room.

These HVLS, high performance fans cover large spaces with the power to move stagnant air approximately 100 ft. in every direction, helping to ensure even temperatures in every corner of your facility.

2. Lowers overall energy costs

Commercial buildings can spend an average of 27% of energy costs on cooling and heating alone, and that number can increase in high square footage industrial buildings. No matter how powerful your HVAC system is, it will not run at optimum efficiency if you don’t have proper airflow.

HVLS fans work alongside your HVAC to make sure the heat stays consistent throughout the building, so you don’t need to set the thermostat as high.

3. Increases employee comfort in the winter

No one wants to work in a sweltering hot warehouse in the summer, and they certainly won’t be any happier freezing in the winter. Studies show that increased employee comfort is directly related to better productivity.

Additionally, comfort and safety work hand-in-hand during the colder months. If your worker’s hands are cold, their dexterity will be affected. Having cold hands is not only uncomfortable, but the poor blood circulation can lead to machine operating or product handling accidents that could have been avoided.

4. Better efficiency leads to greater ROI

High performance HVLS fans only cost a few cents an hour to operate. Combined with the fact that you won’t need to raise your heat as high, your return on investment will increase due to lower heating costs.

This can save business owners up to 30% on energy costs. With those savings, a HVLS fan will pay for itself within the first year of installation..

5. Adjustable settings for direction and speed

Similar to your ceiling fan at home, you can run Rite-Hite’s HVLS fans in reverse. While not as efficient as running the fan in the standard, forward (counter-clockwise) direction, running it in reverse (clockwise) during the colder months of the year will create an updraft that will force warm air near the ceiling down toward the floor.

Running your fan in reverse is commonly used for warehouse applications that require air movement without creating a significant amount of airflow beneath the fan. To address this concern without running your fans in reverse, the adjustable settings also allow the option to run your HVLS fan at half speed or less. This will still allow the mixing of warm air from the ceiling with the cooler air near the floor but with a restricted amount of airflow when needed.

Maintain Maximum Company Efficiency with HVLS Fans

Understanding how HVLS fans work to keep your commercial or industrial business warm in the winter is important for maintaining maximum company efficiency. To learn more about which high performance fan would work best for your company, you can request more information from the experts at Rite-Hite.

Contact Us Find a Rep